China 6 Axis 1800mm Ogwe aka ruru akpaaka ígwè MIG Welding Robotic Arm

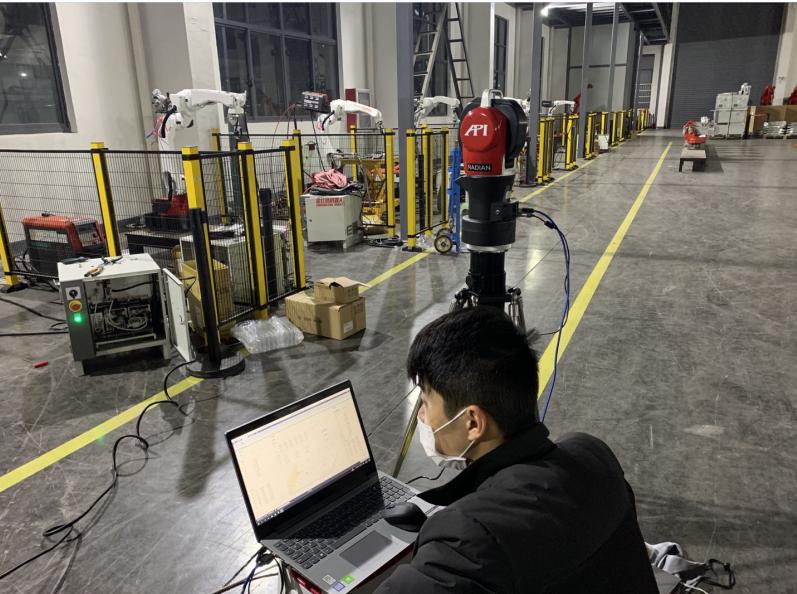

Nnwale Nleghachi nke Laser CALIBRATION EZIOKWU

JHY na-eji usoro nhazi laser iji nwalee izi ezi n'ọkwa nke rọbọt ugboro ugboro.Mgbe ọtụtụ ule gasịrị, izi ezi n'ọkwa nke robot anyị dị elu karịa ± 0.08mm.

Jiri akara kacha elu maka ngwa ngwa isi

Ngwa ngwa robot isi dị ka servo moto, RV reducer, harmonic reducer, servo drive na ihe ndị ọzọ niile na-eji ụdị China kacha mma, nke ejirila ogologo oge nwalere iji hụ na ha dabara maka robot anyị.

Nkwadebe dị mfe

Nlekọta dị mfe, Dị ka ntuziaka nlekọta nyere anyị ndị ahịa onwe ha nwere ike ịrụ ọrụ n'ụzọ dị mfe.

MGBE KWESỊRỊ ire ere gasịrị

Onye ọ bụla na-azụ ahịa nwere otu ọrụ ọrịre ahịa nke ya.Ọ bụrụ na ịchọrọ enyemaka ọ bụla mgbe ịre ahịa gasịrị, Pls jụọ n'oge ọ bụla.Ndị injinia ọkachamara anyị ga-edozi ya n'oge kacha nso.Isi ihe bụ na ọ bụ n'efu.

| Welding parameters kwuru maka nwayọọ ígwè na ala alloy ígwè | |||||||||

| ụdị | efere | Dayameta waya | mgbọrọgwụ oghere | ịgbado ọkụ ugbu a | ịgbado ọkụ voltaji | ịgbado ọkụ ọsọ | Ebe dị anya n'ọnụ-arụ ọrụ kọntaktị | Gas eruba | Nkuku ịgbado ọkụ |

| ịgbado ọkụ n'ụdị T | 1.0 | 0.8 | 2.5–3 | 70–80 | 17-18 | 8-10 | 10 | 10–15 | 45° |

| 1.2 | 1.0 | 3-3.5 | 85–90 | 18-19 | 8-10 | 10 | 10–15 | 45° | |

| 1.6 | 1.0,1.2 | 3-3.5 | 100 ~ 110 | 18-19.5 | 8-10 | 10 | 10–15 | 45° | |

| 2.0 | 1.0,1.2 | 3-3.5 | 115 ~ 125 | 19.5–20 | 8-10 | 10 | 10–15 | 45° | |

| 2.3 | 1.0,1.2 | 3-3.5 | 130 ~ 140 | 19.5–21 | 8-10 | 10 | 10–15 | 45° | |

| 3.2 | 1.0,1.2 | 3.5–4 | 150 ~ 170 | 21–22 | 7.5–8 | 15 | 15-20 | 45° | |

| 4.5 | 1.0,1.2 | 4.5–5 | 180 ~ 220 | 21-23 | 6.5-7.5 | 15 | 15-20 | 45° | |

| 1.2 | 5-5.5 | 200 ~ 250 | 24–26 | 6.5–8 | 10–15 | 10-20 | 45° | ||

| 6 | 1.2 | 5-5.5 | 230 ~ 260 | 25–27 | 6.5-7.5 | 20 | 15-20 | 45° | |

| 6 | 220 ~ 250 | 25–27 | 5.5-7.5 | 13–18 | 10-20 | 45° | |||

| 4-4.5 | 270 ~ 300 | 28-31 | 10 ruo 11.5 | 13–18 | 10-20 | 45° | |||

| 8,9 | 1.2,1.6 | 6–7 | 270 ~ 380 | 29-35 | 6.5-7.5 | 25 | 20-25 | 50° | |

| 8 | 1.2 | 5–6 | 270 ~ 300 | 28-31 | 9–10 | 13–18 | 10-20 | 45° | |

| 1.2 | 7–8 | 260 ~ 300 | 26–32 | 4-5.5 | 15-20 | 10-20 | 50° | ||

| 1.6 | 6.5–7 | 300 ~ 330 | 30–34 | 5-5.5 | 15-20 | 10-20 | 50° | ||

| 12 | 1.2,1.6 | 7–8 | 270 ~ 380 | 27-35 | 4.5-6.5 | 20-25 | 20-25 | 50° | |

| 1.2 | 7–8 | 260 ~ 300 | 26–32 | 4-5.5 | 15-20 | 10-20 | 50° | ||

| 1.6 | 6.5–7 | 300 ~ 330 | 30–34 | 5–6 | 15-20 | 10-20 | 50° | ||

Mara:

1. MIG ịgbado ọkụ na-eji inert gas, tumadi eji maka ịgbado ọkụ nke aluminum na alloys, ọla kọpa na ya alloys, titanium na ya alloys, nakwa dị ka igwe anaghị agba nchara na okpomọkụ na-eguzogide ígwè.A na-ejikarị MAG ịgbado ọkụ na CO2 gas na-echebe ịgbado ọkụ maka ịgbado ọkụ carbon ígwè na ala alloy elu ígwè.

2. Ọdịnaya dị n'elu bụ naanị maka ntụnye aka, ọ kachasị mma ịnweta parampat usoro ịgbado ọkụ kacha mma site na nyocha nnwale.The n'elu waya diameters dabeere n'ezie ụdị.